ABTech’s mechanical-bearing linear stages have high-precision cross roller linear guide rails incorporated that are designed and manufactured in-house to extremely tight geometric tolerances. The result is superior performance in travel straightness, smoothness of motion, high stiffness, repeatability, and accuracy.

Mechanical linear stages are used in a wide range of applications where high-performance motion is required. They are ideal as stand-alone units or multi-axis assemblies, for assembly tools, position measurements, optical scanning, light machining and grinding, and more.

Quality, accuracy, and design flexibility are the reasons why our stages are meeting the ultra-precision motion demands in industries and applications such as aviation, aerospace, automotive, energy (gas, oil, and wind), precision optics, bearings, semiconductors, and medical devices.

Features & Benefits

Superior Mechanical Motion

By leveraging our knowledge and experience gained in producing the extreme tolerances required for air bearings, ABTech mechanical stages are superior in performance and quality. While cross-roller guides can be purchased from many manufacturers, the key to a high-performance stage is in the geometry and overall quality of the mating components.

Configuration Flexibility to Meet Your Specific Needs

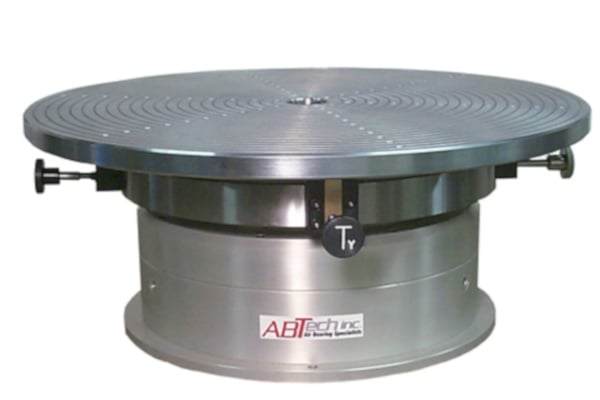

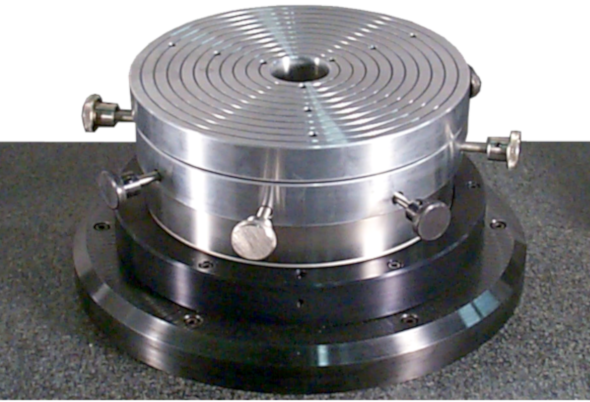

Our precision motion experts will work closely with you to configure a rotary motion solution that will meet your exact needs.

Motor Drives and Controls

High-performance Linear Motors and high-resolution encoders are integrated seamlessly with application specific controls providing a turnkey motion system.

Interested in Getting a Quote?

Motor Drive Options

With proper selection and integration of high-performance brushless DC servo motors ABTech’s air bearing rotary tables provide ultra-smooth and precise rotary motion. With high torque, high performance motor drives, our motion experts will gather your specific requirements and work closely with our motor suppliers to create/select a motor drive that suits your specific application. Whether you need sub-micron position accuracy with minimal settle time and stringent following error specifications, high-speed constant motion, or a combination of both there is an ABTech rotary table that will meet your needs.

The motor drives are designed to accommodate a wide range of precision motion applications such as optical metrology; circular geometry gages; and micro machining with ultra-precision scanning, velocity control, speed regulation and precision indexing.

ABTech’s modular design approach facilitates multiple system configurations to optimize the price-for-performance required in your application. This approach allows the user to define the level of control desired for the most cost-effective solution. Our complete engineering services allow us to respond quickly to provide a solution to your O.E.M. requirements for ultra-precision rotary motion.

See What Our Customers are Saying

"We use 2 ABTech air-bearing spindles with tip/tilt and centering capability in our facility. These units are used for precision assembly and final metrology. We have never had an issue with either one, and the ABTech team is a great partner for us. We will be adding more systems as our young organization continues to grow".

Jayson Tierson

President, Vertex Optics

See What Our Customers are Saying

“Thanks a lot for your help [with remote technical support provided for the system installed at the South Pole]. Your rapid, informative correspondence was invaluable. Hopefully I won't be bothering you with any further questions, but it's good to know you're willing.”

Morgan Hedges

Post-Doctoral Research Associate, Princeton University

FAQ's

Some Lorem ipsum faqs will be here with subheading

Who we are working with?

Adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan lorem ipsum dolor sit amet.

What is the process of purchasing

Adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan lorem ipsum dolor sit amet.

Lorem Ipsum Dolor Sit Amet Consectetur Adipiscing ?

Adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan lorem ipsum dolor sit amet.

Lorem Ipsum Dolor Sit Amet Consectetur Adipiscing ?

Adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan lorem ipsum dolor sit amet.

Why choose us

Aptent taciti sociosqu litora torquent

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan, risus sem sollicitudin lacus, ut interdum tellus elit sed risus.

Made in the U.S.A of U.S. and imported parts

Join our mailing list and never miss an update.