Accuracy is the most important measurement metric, but it isn’t the only one. Efficiency and usability are almost as critical. That means having a gage that is straightforward to use by operators of all skill levels. Our FormCheck™ gages are quicker to set up, easier to use than a CMM, and offer higher accuracy with more reliable results.

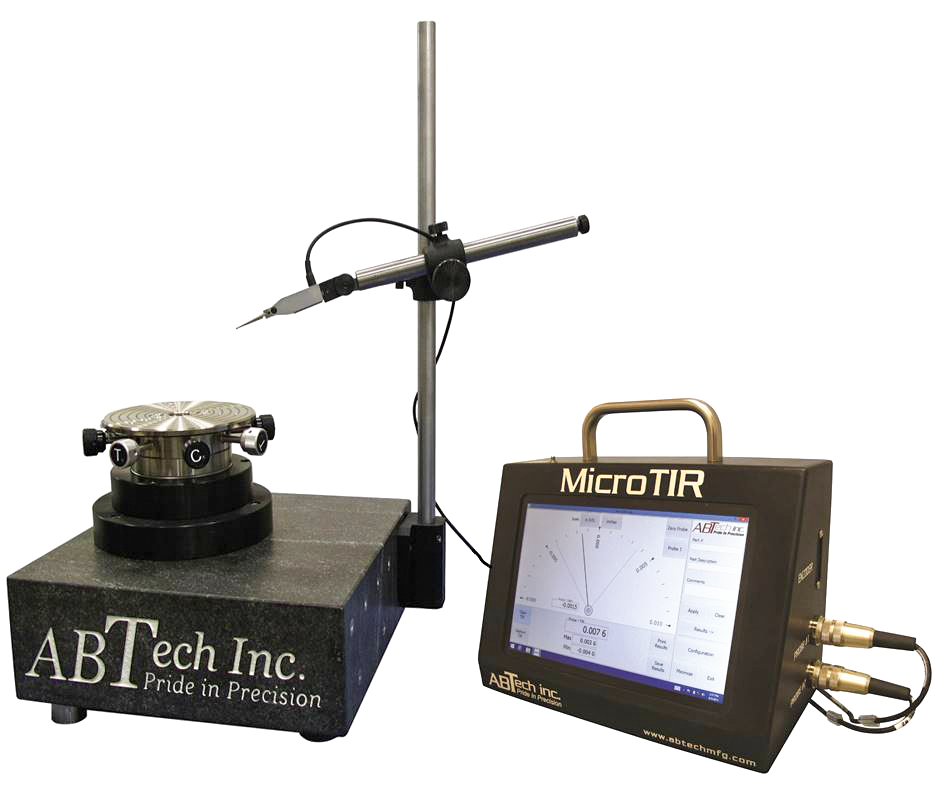

Designed specifically for checking total indicator readings (TIR) on OD, ID, and faces of cylindrical parts, the FormCheck™ is focused on maximizing throughput.

The friction-free ultra-precise air-bearing rotary table provides a stable, robust, and maintenance-free reference axis with certified system accuracy better than 10 millionths of an inch (10μ” or 0.25μm).

The FormCheck™gage basic configuration includes a single, precision lever-type electronic indicator, probe fine adjust, gage stand, air-bearing rotary table with a tilt and center worktable mounted to an inspection grade granite surface plate, and FormCheck™ touch screen display, all of which provide a turnkey system.

The user interface displays the results in both a traditional analog-style needle and a digital format. The maximum and minimum readings and TIR are captured removing potential operator error and user subjectivity. You can input part numbers and descriptions and your results can be saved or printed for customer verification or as a traveler for the part. For a more in-depth explanation of the display please refer to our datasheet on “FormCheck™ Display package”.

This versatile system allows you to measure and verify TIR on a wide array of parts ranging from gears, pistons, and jet-engine components for in-house inspection or incoming part inspections for vendor compliance.

Features & Benefits

Ultra-Smooth operation

Air bearing rotary table providing ultra-smooth, repeatable and maintenance-free operation

Precise Gage Stands

Gage stands designed for precise, stable movement while optimizing ease of use

Tilt & Center Worktable

Standard tilt & center worktable to center and level parts to the bearing’s axis of rotation, reducing eccentricity

Intuitive Interface

Easily readable 10” wide format color touch screen with user friendly software

Enterprise Connectivity

Network capabilities for enterprise connectivity

Comprehensive Reporting

“Stackable” TIR results feature that can be combined into a single exportable report (PDF, CSV, Excel)

Interested in Getting a Quote?

Options & Accessories

- Second probe and gage stand for individual or sum/differential probe display

- Rotary encoder interface to synchronize the probe readings to the rotational position of your part

- Precision centering fixtures, scroll chucks, custom collets and part mounting fixtures

- Certified 2µ” master test ball and cover for system accuracy verification

- Application Specific Solutions. Connect with one of our precision motion experts to configure a measurement solution that will meet your exact needs.

MicroTIR Specifications

| MTIR150 | MTIR200 | MTIR300 | MTIR400 | |

|---|---|---|---|---|

| Bearing Accuracy | ||||

| Radial & Axial | <5.0 µ” (0.125 µm) | |||

| Tilt | <0.206 arc sec or 1.0µ”/in (0.025 µm/25mm) | |||

| Working Envelope | ||||

| Maximum Part Diameter (swing) | 12” 305 mm |

16” 406 mm |

24” 610 mm |

32” 813 mm |

| Maximum Part Height (OD probe acecss) | 16” 406 mm |

18” 457 mm |

24” 610 mm |

36” 1,220 mm |

| Height to Worktable | 10" 254 mm |

32" 813mm |

||

| Axial Load Capacity | *60 lbs *27 Kg |

500 lbs 226 Kg |

1,200 lbs 544 Kg |

2,000 lbs 998 Kg |

| Air Bearing Diameter | 6” 152 mm |

8” 203 mm |

12” 305 mm |

16” 406 mm |

| Tilt & Center Worktable Configuration | ||||

| Thru-hole (with removable plug) |

1.25” 31.75 mm |

1.51” 38.35 mm |

1.75” 44.45 mm |

2.00” 50.80 mm |

| Tapped holes | 1/4 -28 UNF | |||

| Knob Adjustment Configuration | 2 centering, 2 leveling at 90° |

4 centering, 4 leveling at 90° | ||

| Gage Stand Configuration | ||||

| Style | Toolroom style (GST) stand | Inspection style (GSI) stand | ||

| Quantity | Single (standard) & Dual (optional) | |||

| Display Package | ||||

| Software | ABTech MicroTIR Software | |||

| PC | Windows OS Industrial PC with 10” touchscreen | |||

| Misc. Package | ||||

| Product Dimension | 18” W x 12” D x 36” T 457 x 305 x 914 mm |

24” W x 18” D x 58” T 610 x 457 x 1473 mm |

36” W x 24” D x 70” T 914 x 610 x 1778 mm |

54” W x 36” D x 82” T 1372 x 914 x 2083 mm |

| Product Weight | 150 lbs 68 Kg |

900 lbs 408 Kg |

1000 lbs 454 Kg |

1200 lbs 544 Kg |

| Air Consumption | 2.0 cfm @ 60 psi, equipped with dual stage filter/regulator assembly | |||

*Limited by tilt and center worktable. Higher load capacities available upon request.

See What Our Customers are Saying

"We use 2 ABTech air-bearing spindles with tip/tilt and centering capability in our facility. These units are used for precision assembly and final metrology. We have never had an issue with either one, and the ABTech team is a great partner for us. We will be adding more systems as our young organization continues to grow".

Jayson Tierson

President, Vertex Optics

See What Our Customers are Saying

“Thanks a lot for your help [with remote technical support provided for the system installed at the South Pole]. Your rapid, informative correspondence was invaluable. Hopefully I won't be bothering you with any further questions, but it's good to know you're willing.”

Morgan Hedges

Post-Doctoral Research Associate, Princeton University

Benefits and Advantages

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan, risus sem sollicitudin lacus, ut interdum tellus elit sed risus. Maecenas eget condimentum velit, sit amet feugiat lectus. Class aptent taciti sociosqu ad litora torquent per conubia nostra.

Maecenas eget condimentum velit, sit amet feugiat lectus. Class aptent taciti sociosqu ad litora torquent per conubia nostra.

Lorem Ipsum Dolor Sit Amet Consectetur Adipiscing ?

Adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan lorem ipsum dolor sit amet.

Lorem Ipsum Dolor Sit Amet Consectetur Adipiscing ?

Adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan lorem ipsum dolor sit amet.

Lorem Ipsum Dolor Sit Amet Consectetur Adipiscing ?

Adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan lorem ipsum dolor sit amet.

Lorem Ipsum Dolor Sit Amet Consectetur Adipiscing ?

Adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan lorem ipsum dolor sit amet.

FAQ's

Some Lorem ipsum faqs will be here with subheading

Who we are working with?

Adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan lorem ipsum dolor sit amet.

What is the process of purchasing

Adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan lorem ipsum dolor sit amet.

Lorem Ipsum Dolor Sit Amet Consectetur Adipiscing ?

Adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan lorem ipsum dolor sit amet.

Lorem Ipsum Dolor Sit Amet Consectetur Adipiscing ?

Adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan lorem ipsum dolor sit amet.

Why choose us

Aptent taciti sociosqu litora torquent

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan, risus sem sollicitudin lacus, ut interdum tellus elit sed risus.