Features & Benefits

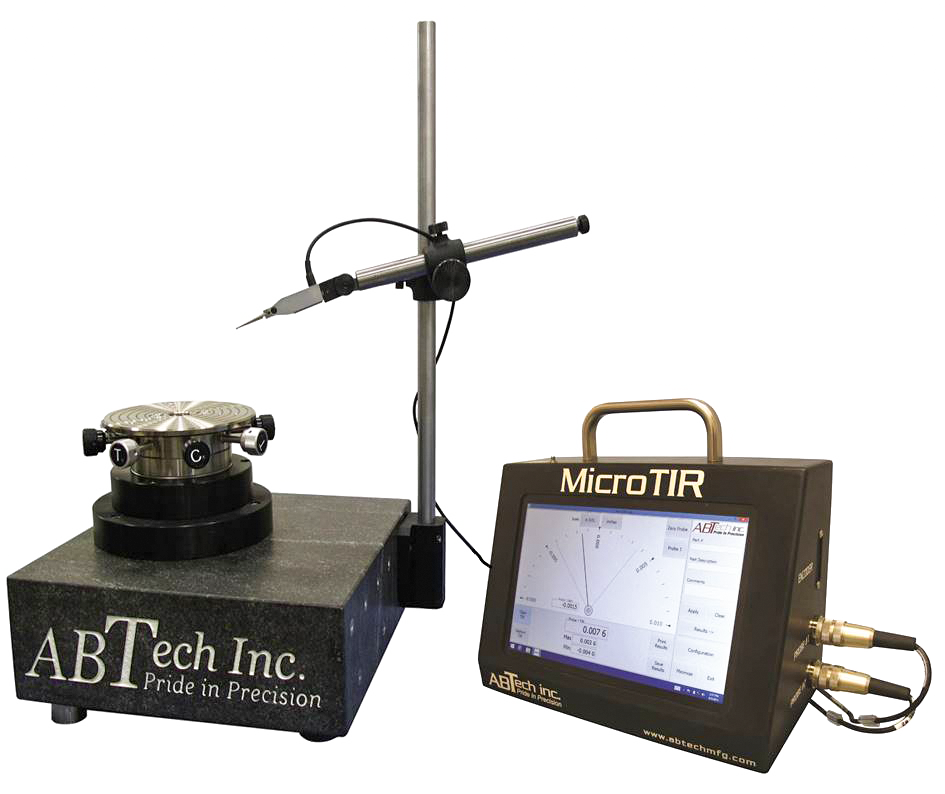

Air bearing rotary table providing ultra-smooth, repeatable and maintenance-free operation

Gage stands designed for precise, stable movement while optimizing ease of use

Standard tilt & center worktable to center and level parts to the bearing’s axis of rotation, reducing eccentricity

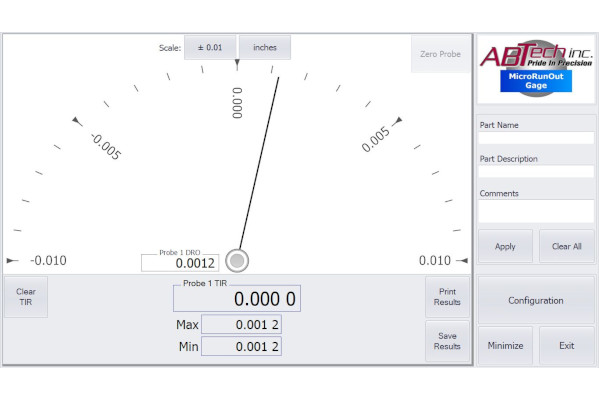

Easily readable 10” wide format color touch screen with user friendly software

Network capabilities for enterprise connectivity

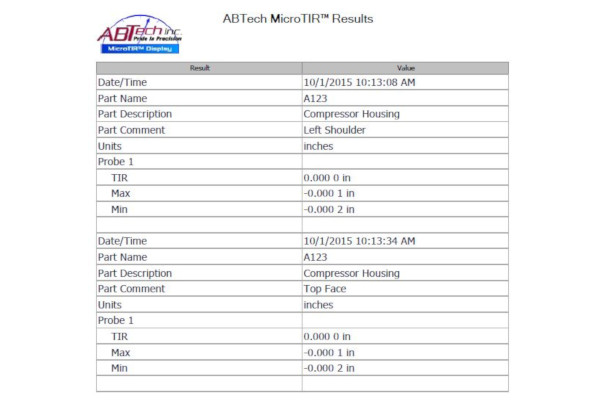

“Stackable” TIR results feature that can be combined into a single exportable report (PDF, CSV, Excel)

Options & Accessories

• Second probe and gage stand for individual or sum/differential probe display

• Rotary encoder interface to synchronize the probe readings to the rotational position of your part

• Precision centering fixtures, scroll chucks, custom collets and part mounting fixtures

• Certified 2µ” master test ball and cover for system accuracy verification

MicroTIR Specifications

| MTIR150 | MTIR200 | MTIR300 | MTIR400 | |

|---|---|---|---|---|

| Bearing Accuracy | ||||

| Radial & Axial | <5.0 µ” (0.125 µm) | |||

| Tilt | <0.206 arc sec or 1.0µ”/in (0.025 µm/25mm) | |||

| Working Envelope | ||||

| Maximum Part Diameter (swing) | 12” 305 mm |

16” 406 mm |

24” 610 mm |

32” 813 mm |

| Maximum Part Height (OD probe acecss) | 16” 406 mm |

18” 457 mm |

24” 610 mm |

36” 1,220 mm |

| Height to Worktable | 10" 254 mm |

32" 813mm |

||

| Axial Load Capacity | *60 lbs *27 Kg |

500 lbs 226 Kg |

1,200 lbs 544 Kg |

2,000 lbs 998 Kg |

| Air Bearing Diameter | 6” 152 mm |

8” 203 mm |

12” 305 mm |

16” 406 mm |

| Tilt & Center Worktable Configuration | ||||

| Thru-hole (with removable plug) |

1.25” 31.75 mm |

1.51” 38.35 mm |

1.75” 44.45 mm |

2.00” 50.80 mm |

| Tapped holes | 1/4 -28 UNF | |||

| Knob Adjustment Configuration | 2 centering, 2 leveling at 90° |

4 centering, 4 leveling at 90° | ||

| Gage Stand Configuration | ||||

| Style | Toolroom style (GST) stand | Inspection style (GSI) stand | ||

| Quantity | Single (standard) & Dual (optional) | |||

| Display Package | ||||

| Software | ABTech MicroTIR Software | |||

| PC | Windows OS Industrial PC with 10” touchscreen | |||

| Misc. Package | ||||

| Product Dimension | 18” W x 12” D x 36” T 457 x 305 x 914 mm |

24” W x 18” D x 58” T 610 x 457 x 1473 mm |

36” W x 24” D x 70” T 914 x 610 x 1778 mm |

54” W x 36” D x 82” T 1372 x 914 x 2083 mm |

| Product Weight | 150 lbs 68 Kg |

900 lbs 408 Kg |

1000 lbs 454 Kg |

1200 lbs 544 Kg |

| Air Consumption | 2.0 cfm @ 60 psi, equipped with dual stage filter/regulator assembly | |||

*Limited by tilt and center worktable. Higher load capacities available upon request.

Specialized Custom Solutions

No matter how broad our standard product options may be, we realize that they can’t address every possible application. That’s what separates ABTech from most other Metrology suppliers. We won’t say 'sorry, best of luck.' Rather, we’ll connect you with one of our precision motion experts and work closely with you to configure a measurement solution that will meet your exact needs. This includes developing custom solutions for the most unique applications.

We use 2 ABTech air-bearing spindles with tip/tilt and centering capability in our facility. These units are used for precision assembly and final metrology. We have never had an issue with either one, and the ABTech team is a great partner for us. We will be adding more systems as our young organization continues to grow.Jayson TiersonPresident

Vertex Optics

Every product we sell exemplifies our company-wide commitment to "Pride in Precision" craftsmanship. To that end, all of our products are designed, manufactured, and tested exclusively by ABTech at our New Hampshire facility.