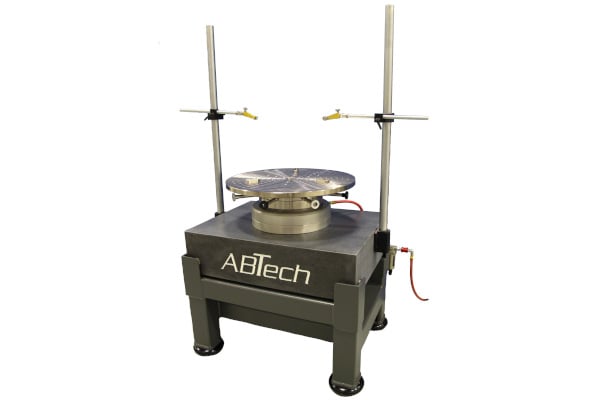

Microform Roundness Gages

We have a full line of air-bearing-based roundness gages for checking roundness, runout, flatness, concentricity, parallelism, and perpendicularity. With our commitment to simplistic precision, we developed an easy-to-use and intuitive front-end software package and robust mechanical platform resulting in the best value on the market. Our standard roundness gage models measure parts up to 32 inches in diameter and 2,000 lbs in weight.

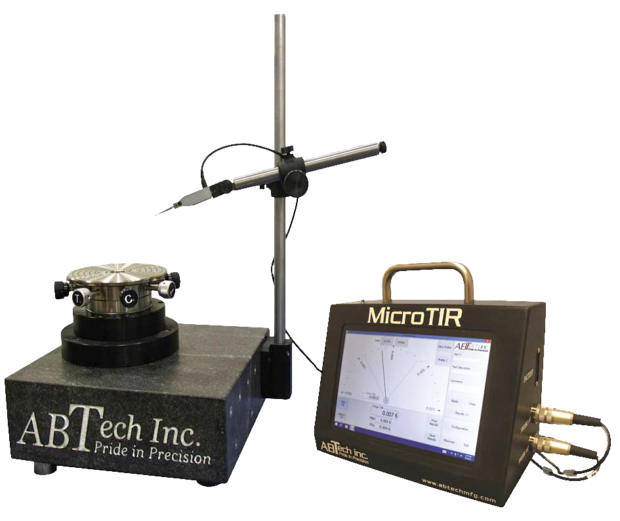

MicroTIR Gages

Don’t need a full roundness gage? ABTech offers a full line of total indicator reading gages for quick measurements of TIR on ODs, IDs, and faces of precision cylindrical parts. Using the same air-bearing rotary tables, tilt and center tables and gage stands as our roundness gage product line, our standard gages measure parts up to 32 inches in diameter and 2,000 lbs in weight.

LEARN MORE

Diameter Measurement Gage

Do you need to check the size of your large turned parts while still on the lathe, grinder, or other machine center? ABTech’s precision diameter measurement gage is designed for measuring large diameter parts in process to 0.001” system accuracy. Our touchpad user interface and software front-end package is simple to use and intuitive. Our standard receiver mount fits Aloris C5 Capto tool holders with custom mount available.

LEARN MORE

Thickness Gages

Do you need to measure the thickness of your lens or precision ground or lapped parts to better than +/- 20 micro inches? We offer a variety of thickness gages with single or dual probe options. Custom fixtures and sizes are available on request as well.

LEARN MORE

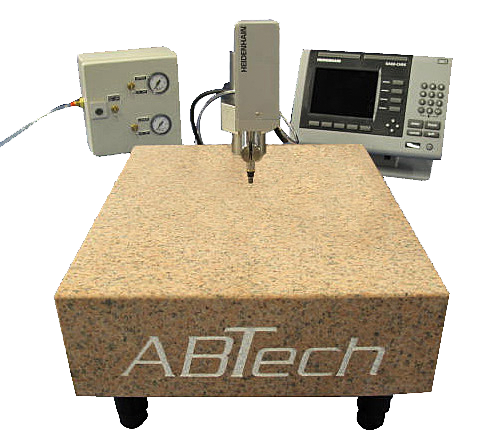

Setting Master

ABTech offers a setting master that uses a natural granite base and air-bearing slide for the setup of ID/OD beam gages such as Federal Products Series 980. Standard position accuracy of +/- 0.00024” over 80” of travel with the ability to compensate for tighter accuracy if needed is just one of the many benefits.

LEARN MORE

Accessories

ABTech offers a variety of accessories to fit your required mechanical needs. These include, tilt and center worktables, motor drives and controls, encoders and amplifiers, dual-element filter/regulators, granite surface plates, standard and custom sized clear apertures, and custom fixturing. Each accessory is tailored to fit your specific need.

LEARN MOREIndustries:

We use 2 ABTech air-bearing spindles with tip/tilt and centering capability in our facility. These units are used for precision assembly and final metrology. We have never had an issue with either one, and the ABTech team is a great partner for us. We will be adding more systems as our young organization continues to grow.Jayson TiersonPresident

Vertex Optics

Every product we sell exemplifies our company-wide commitment to "Pride in Precision" craftsmanship. To that end, all of our products are designed, manufactured, and tested exclusively by ABTech at our New Hampshire facility.