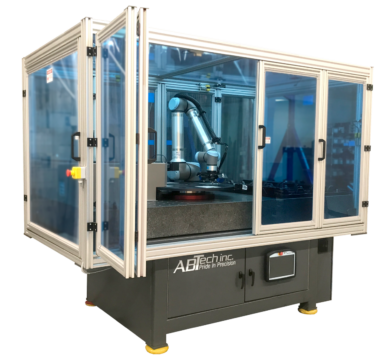

Measurement & Loading System for Optical Film Measurement

ABTech’s fully automated air-bearing system measures, serializes, and sorts ultra-thin optical films for manufacturing gradient, refractive index (GRIN) lenses. This system is an AT300/800 air-bearing turntable with a SP138 air-bearing spindle. It includes dual high-resolution encoders for precise positioning and DAQ. A UR10e collaborative robot with custom vacuum and anti-static tooling and a laser station that provides and measures beam path through SP138 centerline, with 4 expandable film stations and additional service stations.

Learn More

5-Axis Air-Bearing Positioning System

ABTech’s 5-axis air-bearing project was designed and built for the National Ignition Facility at Lawrence Livermore Labs. The National Ignition Facility, or NIF, is a stadium-sized facility used to study advances in fusion energy; it contains 192 laser beams that are focused on a single target that is only 0.022” in diameter. These targets are made up of several double-shell layers that are diamond-turned and epoxied together.

Learn More

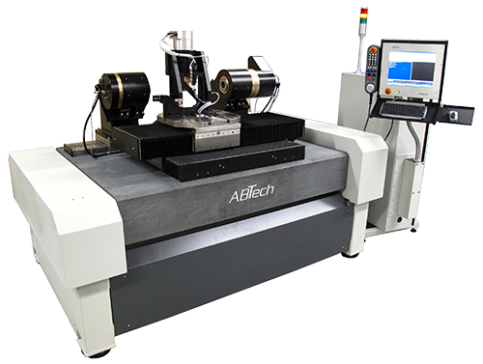

Multi-Functional Machines for NASA NuStar X-Ray Telescope

NASA needed a machine that would safely and quickly produce optics for their long-delayed NuSTAR x-ray telescope. The scientists at NASA challenged ABTech to develop a multifunctional machine that would act as a diamond turning lathe, an indexing tool for raster grinding and an assembly station – all in one. ABTech met the challenge. Two machines were delivered to Columbia University’s Nevis Astrophysics Lab in quick fashion, putting the project back on schedule.

Learn More

Sonnax Air-Bearing Lathe and Metrology Work Cell

Increasingly tighter part tolerances on transmission parts made it more difficult for typical off-shore sourcing channels to meet the quality standards being demanded by the major automotive manufacturers. To solve this international sourcing logistics problem, a leading manufacturer of OEM automotive parts contracted ABTech to design and manufacture a turnkey work cell.

Learn More

Custom Rail Air-Bearing Imaging Spindle

ABTech designed a set of three high-speed air-bearing spindles that were synchronized for the 3-dimensional image scanning and inline inspection, to inspect the track, switches, tunnels, and bridges for potential maintenance issues, the system was mounted on a dedicated rail car traveling at 75 mph allowing the spindles to create a 3-D image of the rail every 10 cm (less than 4″).

Learn More

5-Axis Air-Bearing Optical Measurement Metrology Platform

OptiPro Systems, a well-respected optical machine manufacturer, contacted ABTech thinking they simply needed a supplier of air-bearing stages for the development of a prototype metrology station. When the dust settled, the best path to their solution was leveraging OptiPro’s core competencies in optics and ABTech’s core competencies in air-bearing-based metrology systems.

Learn More

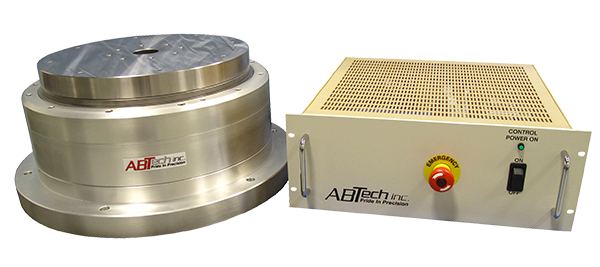

AT400 Direct Drive Rotary Air-Bearing Installed at the South Pole

Researchers at Princeton University needed a large diameter ultra-precision rotational axis with a motor drive. Sounds routine. But there were some catches that made this project more than a bit unusual.

First, the entire research project needed to be installed on the top of a rotary table. Second, they needed to run their tests continuously over a period of several weeks. Third, their sensitivity level was so high that the system had to be installed at the South Pole to eliminate the effects of the earth’s rotation.

Learn MoreIndustries:

We use 2 ABTech air-bearing spindles with tip/tilt and centering capability in our facility. These units are used for precision assembly and final metrology. We have never had an issue with either one, and the ABTech team is a great partner for us. We will be adding more systems as our young organization continues to grow.Jayson TiersonPresident

Vertex Optics

Every product we sell exemplifies our company-wide commitment to "Pride in Precision" craftsmanship. To that end, all of our products are designed, manufactured, and tested exclusively by ABTech at our New Hampshire facility.