Features & Benefits

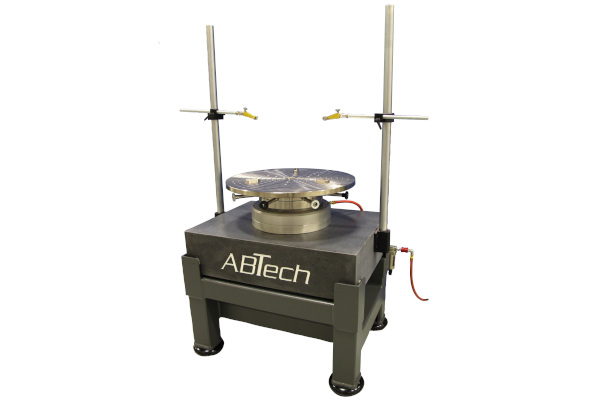

Air bearing rotary table providing ultra-smooth, repeatable and maintenance-free operation

Highly responsive lever-type probe with excellent linearity over the full travel

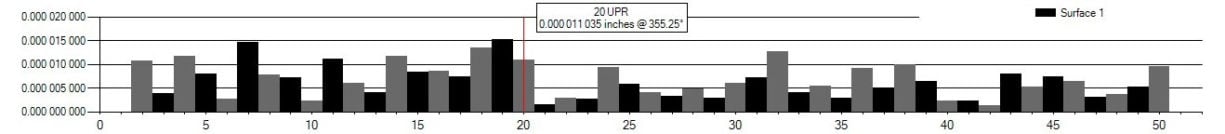

Real-time operating system with FPGA processing platform and signal conditioners eliminating resource conflicts typical with systems running on PC’s

Gage stands designed for precise, stable movement while optimizing ease of use

Standard tilt & center worktable to center and level parts to the bearing’s axis of rotation reducing eccentricity, increasing accuracy of results and reduces time and frustration during setup of the part for measurement

Intuitive navigation for shop floor use as well as full function analysis for quality control labs

Step-by-step instructions for novice operators without reducing efficiency for experienced users

Touch screen color monitor

Easily customizable outputs and display settings such as filter, plot scale, units, and analysis type

Options

- Optional integrated motor drive

- Universal style gage stand on a T-slot base (replaces the articulating arm style)

- Second gage stand and probe with dual-probe software upgrade

- Vacuum worktable and controller to hold sensitive lightweight parts

safely and securely

Accessories

- Various probe lengths, tip diameters and materials

- Welded steel base frames with vibration isolation leveling casters

- Electronics cart to house PC, monitor and MicroForm controller

- Precision centering fixtures, custom collets and part-specific fixtures

- Certified 2µ” round master test ball and cover for system accuracy verification

MicroForm Spec Sheet Table

| μFG100 | μFG150 | μFG200 | μFG200T | μFG300 | μFG400 | |

| System Accuracy | ||||||

| Radial & Axial | <5.0 μ" (0.125μm) | |||||

| Tilt | <.2 or 1.0μ"/in (0.25μm/25mm) | |||||

| Working Envelope | ||||||

| Maximum Part Diameter (swing) |

8" 203mm |

12" 305mm |

16" 406mm |

16" 406mm |

24" 610mm |

32" 813mm |

| Maximum Part Height (OD probe access) |

12" 305mm |

16" 406mm |

20" 508mm |

36" 914mm |

60" 1.524m |

60" 1.524m |

| Height to Worktable | 8.75" / 222mm | 9.60" / 244mm | 40" / 1.041m | 41" / 1.041m | 37" / 940mm | 30" / 762mm |

| Axial Load Capacity | 60 lbs / 27 Kg | 125 lbs / 57 Kg | 500 lbs / 226 Kg | 500 lbs / 226 Kg | 1,000 lbs / 454 Kg | 2,000 lbs / 907 Kg |

| Tilt & Center Worktable Configurations | ||||||

| Diameter | 6" / 150mm | 6" / 150mm | 8" / 203mm | 8" / 203mm | 12" / 305mm | 16" / 406mm |

| Thru-hole (removable plug) |

1.25" 31.75mm |

1.25" 31.75mm |

1.51" 38.35mm |

1.51" 38.35mm |

1.75" 44.45mm |

2.00" 50.80mm |

| Tapped Holes | 1/4 - 28 tapped holes | |||||

| Knob Configuration | 2 centering, 2 leveling at 90° |

4 centering, 4 leveling at 90° | ||||

| Gage Stand Configuration | ||||||

| Style | "High Output" Articulating Arm | Mini Tower | Counterbalance Tower | |||

| Quantity | Single | Single(standard) & Dual Probe (option) | ||||

| Misc. Details | ||||||

| Software | ABTech Micro TIR Software | |||||

| Metrology Controller | "FPGA" based "real-time" operating system housed in surface plate |

Independent electrical box contains "FPGA" based "real-time" operating |

||||

| PC | Windows OS Industrial PC with 10" touchscreen | Windows OS Industrial PC with 22" touchscreen | ||||

| Air Consumption | 2.0 cfm @ 60psi, equipped with dual stage filter/regulator assembly | |||||

| Product Dimension | 10" W x 12" D x 28" T | 16" W x 16" D x 32" T | 20" W x 24" D x 62" T | 26" W x 20" D x 92" T | 77" W x 42" D x 106" T | 90" W x 42" D x 106" T |

| 254 x 305 x 711 mm | 406 x 406 x 813 mm | 508 x 610 x 1575 mm | 914 x 508 x 2337 mm | 1956 x 1067 x 2692 mm | 2286 x 1067 x 2692 mm | |

| Product Weight | 60 lbs | 120 lbs | 400 lbs | 650 lbs | 2300 lbs | 2600 lbs |

| 27 kg | 55 kg | 180 kg | 295 kg | 1050 kg | 1180 kg | |

We use 2 ABTech air-bearing spindles with tip/tilt and centering capability in our facility. These units are used for precision assembly and final metrology. We have never had an issue with either one, and the ABTech team is a great partner for us. We will be adding more systems as our young organization continues to grow.Jayson TiersonPresident

Vertex Optics

Every product we sell exemplifies our company-wide commitment to "Pride in Precision" craftsmanship. To that end, all of our products are designed, manufactured, and tested exclusively by ABTech at our New Hampshire facility.