Selecting the Right Linear Stage

ABTech's advanced precision guide to application-specific solutions for our linear stages

VIEW THE GUIDE

Precision That Pushes the Limits

How ABTech helped launch NASA's NuSTAR telescope

DOWNLOAD THE CASE STUDY

Ask the Expert: How to Choose the Right Air-Bearing Spindles

ABTech President Ken Abbott shares his insight on high-precision air-bearing spindles

DOWNLOAD THE CASE STUDY

Precision Air Bearing Spindle for High Speed Rail Inspection

DOWNLOAD THE CASE STUDY

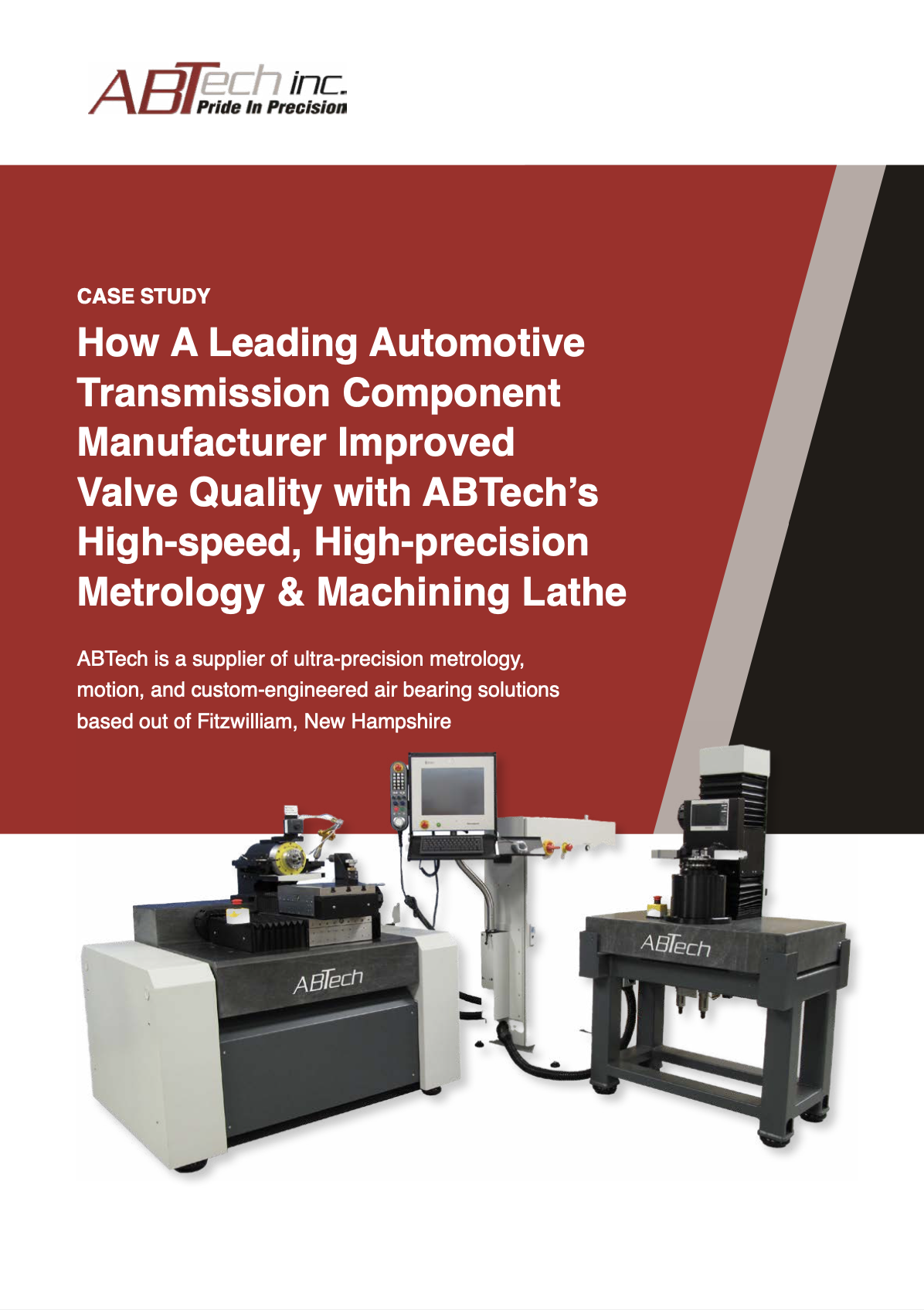

How a Leading Automotive Transmission Component Manufacturer Improved Valve Quality with ABTech's High-speed, High-precision Metrology & Machining Lathe

DOWNLOAD THE CASE STUDY

An Optical Machine-Tool Builder’s Guide to Customizing High-Speed Spindles

DOWNLOAD THE WHITEPAPER

GE Vernova Shares How a Custom-Built, Large-Capacity Runout Inspection Table Helped Speed Up Rotor repair & Assembly

DOWNLOAD THE CASE STUDY

Accuracy in Turbine Rotor Assembly:

Defining The Max Capacity Of Ultra-Precision Rotary Tables

DOWNLOAD THE WHITEPAPER

Optical Machine Tool Innovation Guide:

4 Key Strategies

DOWNLOAD THE WHITEPAPER

ABTech creates the first measurement & automatic loading system for ultra‐precise, ultra‐thin optical films

VIEW THE CASE STUDY

Application-Specific Solutions

While ABTech has a plethora of standard products, we also offer custom designed and manufactured products to suit any customer’s needs. We are constantly pushing the envelope to engineer solutions that others will not take on, and meet our customer’s most challenging specifications.

Our ability to assimilate complex geometric metrology and machining projects, along with our willingness to collaborate has earned ABTech respect from industry leaders and university research centers across the world. If you have a need for an application-specific solution, we are here to be your partner.

LEARN MORE ABOUT CUSTOM SOLUTIONSIndustries:

We use 2 ABTech air-bearing spindles with tip/tilt and centering capability in our facility. These units are used for precision assembly and final metrology. We have never had an issue with either one, and the ABTech team is a great partner for us. We will be adding more systems as our young organization continues to grow.Jayson TiersonPresident

Vertex Optics

Every product we sell exemplifies our company-wide commitment to "Pride in Precision" craftsmanship. To that end, all of our products are designed, manufactured, and tested exclusively by ABTech at our New Hampshire facility.