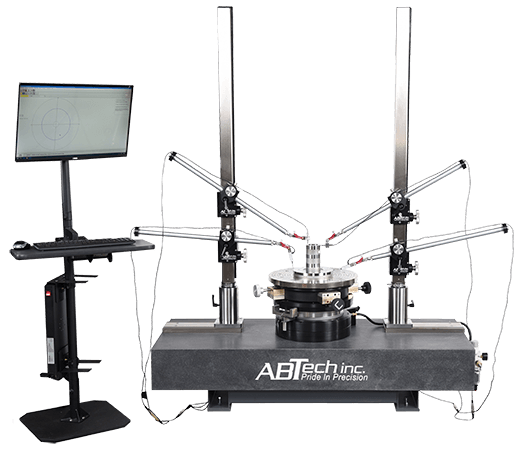

Engine assembly systems are used worldwide to align and assemble high-pressure compressors and turbines (HPCR and HPTR) for jet engine and land-based gas turbine applications.

These engine Assembly systems feature ultra-precision air-bearing rotary tables and rotary encoders that are mounted to natural granite bases for durability and stability, ensuring the highest accuracy and repeatability.

With our heavy-duty adjustable tilt and center worktables, operators can easily bring the engine part precisely in alignment to the air bearings’ rotational axis. The spherical seat design on the worktable maintains the part’s center point when leveling, saving time in setting up for measurement and assembly.

Each system comes with a swing-away gage stands or taller counterbalanced gage towers allowing easy access when loading parts or unloading finished assemblies. Each gage configuration is able to mount up to 8 electronic indicators plugged into the state-of-the-art USB controller making quick work of setup and measurement.

ABTech is a licensed supplier of GE Aerospace Genspect systems including USB controllers and stack prediction software. The controller has inputs for up to 8 LVDT gage heads and the rotary encoder from the air bearing table as well as a USB interface for PCs. And engine assembly system from ABTech now comes complete with the air-bearing platform, controller, required lever and plunger-type probes, Genspect software preloaded in a Windows-based computer, a large color monitor in a heavy-duty mobile electronics cart. A turnkey solution for component inspection and assembling jet engines and turbines.

Our EAS Product Portfolio

Interested in Starting a Conversation?

Contact Our Team For a Quote

Options & Accessories

- Complete Genspect systems with LVDT probes, controller, PC and software

- Lever and plunger type electronic gage heads and extension cables

- Fine adjust probe mounts

- Magnetic base portable gage stands

- Mobile electronics cart with heavy-duty casters and articulating monitor mount

- Fixed base space-saving electronics rack with articulating monitor mount

- Certified 2μ” round master test ball and cover

Features & Benefits

High-Precision Components

Ultra-precision rotary air bearing tables, fine adjust tilt and center worktables, and high-resolution rotary encoders for angular feedback.

Specialized Features

Anti-rotation device for torquing engine bolts and multiple gage stand or tower configurations.

Robust Construction

Granite base and frame with passive isolation feet for stability.

Enhanced Electronics

Electronic gage heads, plunger probes, and optional Genspect electronics with software integration.

See What Our Customers are Saying

"We use 2 ABTech air-bearing spindles with tip/tilt and centering capability in our facility. These units are used for precision assembly and final metrology. We have never had an issue with either one, and the ABTech team is a great partner for us. We will be adding more systems as our young organization continues to grow".

Jayson Tierson

President, Vertex Optics

See What Our Customers are Saying

“Thanks a lot for your help [with remote technical support provided for the system installed at the South Pole]. Your rapid, informative correspondence was invaluable. Hopefully I won't be bothering you with any further questions, but it's good to know you're willing.”

Morgan Hedges

Post-Doctoral Research Associate, Princeton University

Benefits and Advantages

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan, risus sem sollicitudin lacus, ut interdum tellus elit sed risus. Maecenas eget condimentum velit, sit amet feugiat lectus. Class aptent taciti sociosqu ad litora torquent per conubia nostra.

Maecenas eget condimentum velit, sit amet feugiat lectus. Class aptent taciti sociosqu ad litora torquent per conubia nostra.

Lorem Ipsum Dolor Sit Amet Consectetur Adipiscing ?

Adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan lorem ipsum dolor sit amet.

Lorem Ipsum Dolor Sit Amet Consectetur Adipiscing ?

Adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan lorem ipsum dolor sit amet.

Lorem Ipsum Dolor Sit Amet Consectetur Adipiscing ?

Adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan lorem ipsum dolor sit amet.

Lorem Ipsum Dolor Sit Amet Consectetur Adipiscing ?

Adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan lorem ipsum dolor sit amet.

FAQ's

Some Lorem ipsum faqs will be here with subheading

Who we are working with?

Adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan lorem ipsum dolor sit amet.

What is the process of purchasing

Adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan lorem ipsum dolor sit amet.

Lorem Ipsum Dolor Sit Amet Consectetur Adipiscing ?

Adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan lorem ipsum dolor sit amet.

Lorem Ipsum Dolor Sit Amet Consectetur Adipiscing ?

Adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan lorem ipsum dolor sit amet.

Why choose us

Aptent taciti sociosqu litora torquent

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan, risus sem sollicitudin lacus, ut interdum tellus elit sed risus.