Features & Benefits

Accurate, Repeatable, Smooth Motion

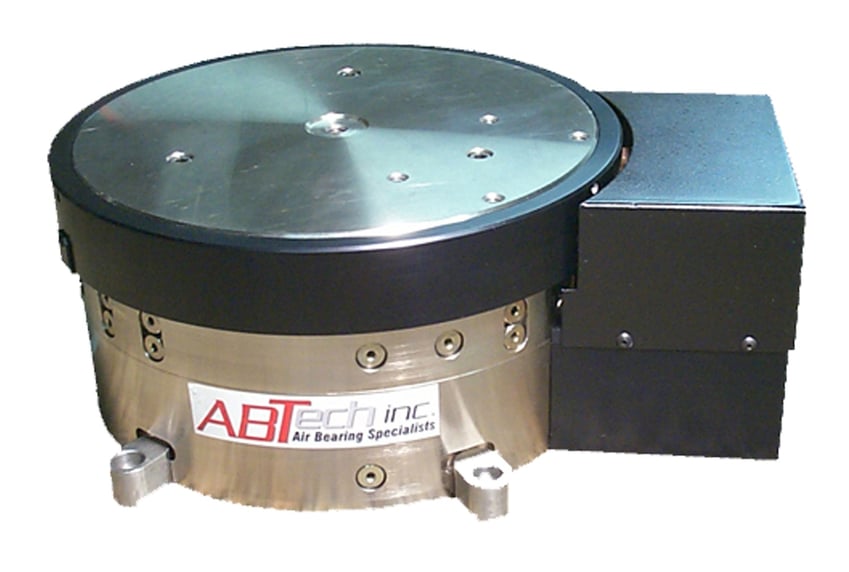

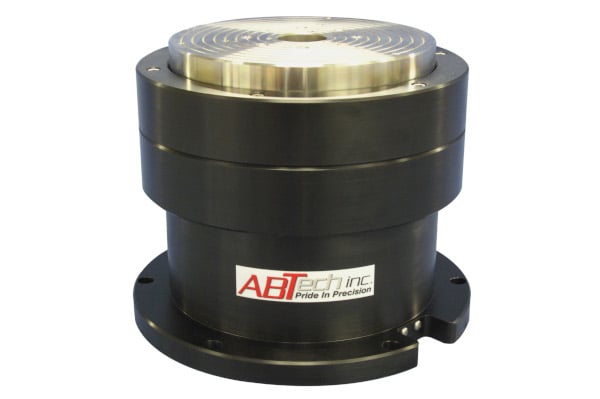

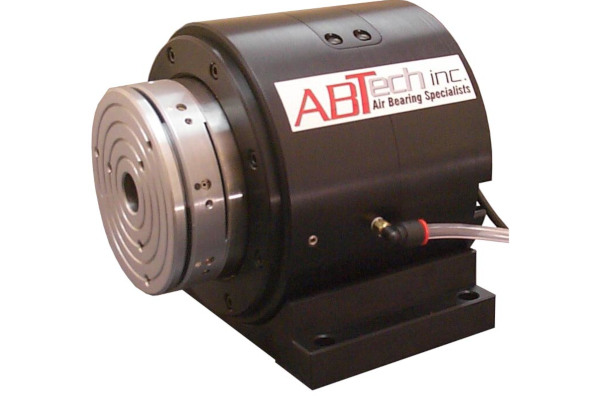

Similar to air bearings, hydrostatic bearings provide significant advantages over mechanical bearings or other approaches to rotary motion. Because they have no mechanical contacting parts to wear, or create drag, hydrostatic bearings are close to frictionless, providing ultra-smooth, repeatable and maintenance-free motion.

Superior Durability

ABTech uses hardened 440C stainless steel components to maximize productivity with applications that require integrating motion systems into production and assembly processes with exposure to harsher environments. Durability of our stages affords forgiveness for minor accidental touch downs resulting from low oil pressure or excessive loading. If an accident occurs, often the bearing needs repair rather than replacement.

Configuration Flexibility to Meet Your Specific Needs

Part of our “Pride in Precision” philosophy means providing you with the precise solution needed. We don’t believe in selling our customers more, or less than what their application calls for. Each ABTech hydrostatic rotary table is designed and built per your specific needs. There is no standard specification sheet or drawings on our website. Each stage is uniquely adapted to our customer, therefore expectations are always met and exceeded. No matter how broad our product options are, we realize they don’t address every possible application. Our precision motion experts will work closely with you to configure a rotary motion solution that will meet your exact needs

Options

- Motor drives and controls

- Encoders and digital readouts (DRO)

- Vacuum worktable and controller to hold sensitive lightweight parts safely and securely

- Custom bolt circle patterns

- Standard and custom size clear apertures

- Hydrostatic Pump Unit (HPU)

Accessories

- Custom fixturing and work holder tooling

- Gage stands

- MicroTIR electronic gage packages

- µTIR-10: display with single lever-type electronic indicator

- µTIR-11: display with single lever-type electronic indicator and encoder interface

- µTIR-20: display with dual lever-type electronic indicators

- µTIR-21: display with dual lever-type electronic indicators and encoder interface

- Granite surface plates

- Structural steel frames with passive vibration isolation leveling feet

- Certified 2µ” round master test ball and cover

Motor Drive Options

With proper selection and integration of high-performance brushless DC servo motors ABTech’s air bearing rotary tables provide ultra-smooth and precise rotary motion. With high torque, high performance motor drives, our motion experts will gather your specific requirements and work closely with our motor suppliers to create/select a motor drive that suits your specific application. Whether you need sub-micron position accuracy with minimal settle time and stringent following error specifications, high-speed constant motion, or a combination of both there is an ABTech rotary table that will meet your needs.

The motor drives are designed to accommodate a wide range of precision motion applications such as optical metrology; circular geometry gages; and micro machining with ultra-precision scanning, velocity control, speed regulation and precision indexing.

ABTech’s modular design approach facilitates multiple system configurations to optimize the price-for-performance required in your application. This approach allows the user to define the level of control desired for the most cost-effective solution. Our complete engineering services allow us to respond quickly to provide a solution to your O.E.M. requirements for ultra-precision rotary motion.

.jpg)

.jpg)

.jpg)

.jpg)

We use 2 ABTech air-bearing spindles with tip/tilt and centering capability in our facility. These units are used for precision assembly and final metrology. We have never had an issue with either one, and the ABTech team is a great partner for us. We will be adding more systems as our young organization continues to grow.Jayson TiersonPresident

Vertex Optics

Every product we sell exemplifies our company-wide commitment to "Pride in Precision" craftsmanship. To that end, all of our products are designed, manufactured, and tested exclusively by ABTech at our New Hampshire facility.