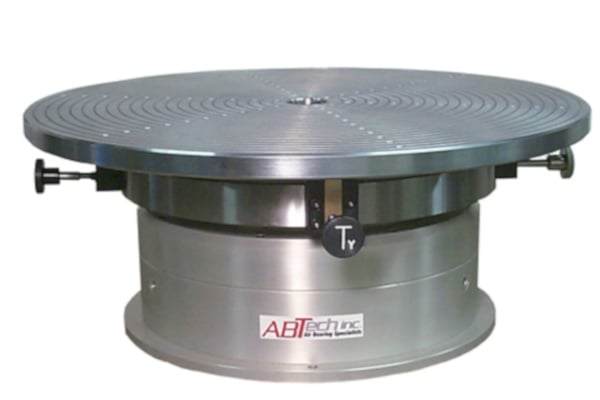

AT Series – Rotary Air Bearing Table

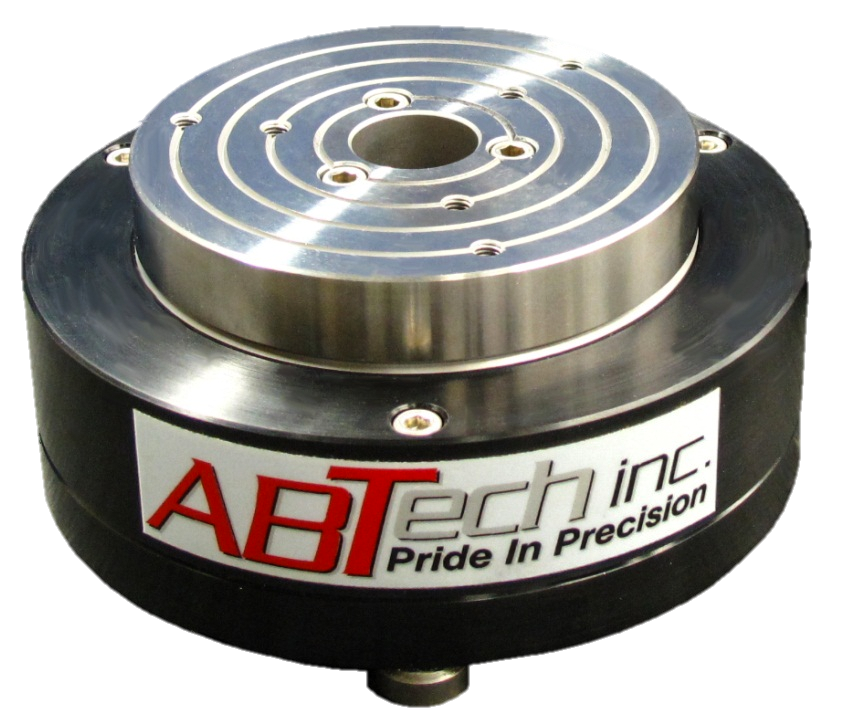

AT300 Rotary Air Bearing

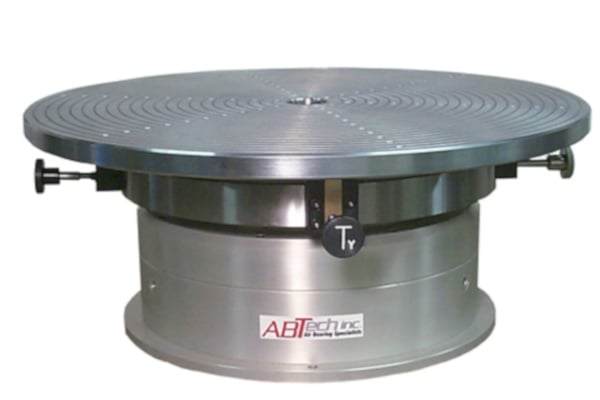

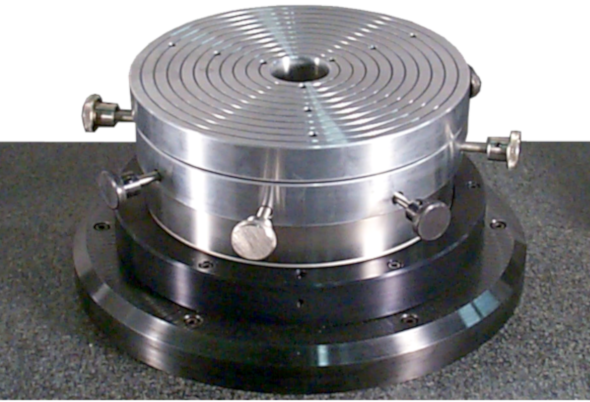

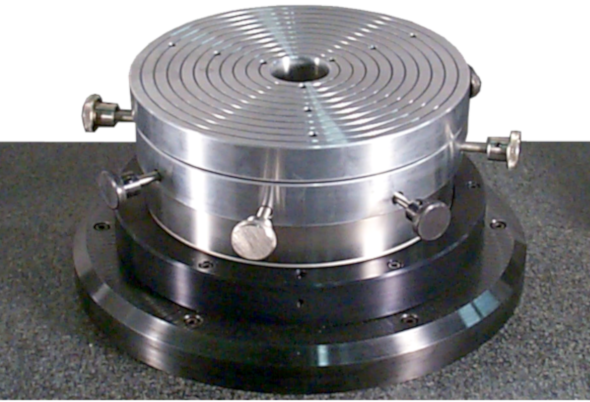

HDRT Series – Rotary Air Bearing Table

HDRT 3000

ABTech’s precision air-bearing rotary tables address the metrology needs for different weights and part sizes. Built for the most demanding applications, every table provides ultra-smooth motion, sub-micron accuracy, and absolute repeatability. They are designed and manufactured in-house to extremely tight geometric tolerances and have no mechanical contacting parts to wear or create drag. This allows for decades of reliable maintenance-free motion.

ABTech’s AT models come standard with dual-element filters/regulators and are commonly used as the core axis in equipment checking total indicator reading (TIR), roundness, flatness, squareness, perpendicularity, concentricity, and parallelism measurements. To speed up part setup and increase productivity, the AT model tables also come standard with our industry-best adjustable tilt and center (tip/tilt) worktables.

Overall, the AT models are ideal as stand-alone units for checking runout of turned parts, optical lens alignment, assembly applications, precision indexing, and light machining or grinding.

The heavy-duty HDRT tables complete the product family. The tilt and center are optionally available for these models. And these HRT tables are a perfect solution for large part applications.

Features & Benefits

Accurate, Repeatable, Smooth Motion

Manufactured with tight geometric tolerances, our air bearings deliver the ultimate in accuracy with radial and axial error motion of as little as 1.0 µ” (25.0 nanometers) and angular errors (coning) of 0.5 µ” per inch (12.5 nanometers/25mm). Air bearings have no mechanical contacting parts to wear, or create drag. They are close to frictionless, providing ultra-smooth, repeatable and maintenance-free motion.

Superior Durability

Manufactured with hardened 440C stainless steel components for many years of service and investment longevity.

Configuration Flexibility to Meet Your Specific Needs

Our precision motion experts will work closely with you to configure a rotary motion solution that will meet your exact needs.

Air-Bearing Rotary Table Specifications

| AT200 | AT300 | AT400 | HDRT500 | HDRT600 | ||

|---|---|---|---|---|---|---|

| Certified Accuracy | ||||||

| Radial & Axial | <2.0 µ" (0.05 µm) | <10.0 µ" (0.250 µm) | ||||

| Tilt (Coning) | <0.206 arc sec or 1.0µ”/in (0.025 µm/25mm) | |||||

| Working Envelope | ||||||

| Maximum Part Diameter (swing) |

16" 406 mm |

24" 610 mm |

32" 813 mm |

40" 1.0 m |

48" 1.2 m |

|

| Axial Load Capacity | 500 lbs 226 Kg |

1,200 lbs 544 Kg |

2,000 lbs 907 Kg |

3,000 lbs 1,361 Kg |

5,000 lbs 2,268 Kg |

|

| Worktable Diameter | 8″ 203 mm |

12″ 305 mm |

16″ 406 mm |

20" 508 mm |

24” 610 mm |

|

| Tapped holes | 1/4 -28 UNF | |||||

| Worktable Configuration | ||||||

| Tilt and Center | 8-knob spherical seat | n/a | ||||

| Knob Configuration | 4 centering , 4 leveling at 90⁰ | n/a | ||||

| Air Consumption | 2.0 cfm @ 60 psi with dual stage filter/regulator | 4.0 cfm @ 60 psi with dual stage filter/regulator | ||||

| Product Dimension | 12.63" OD x 7.25" T 321 x 184 mm |

17.25" OD x 8.50" T 438 x 216 mm |

19.00" OD x 8.00" T 483 x 203 mm |

22.00" OD x 3.40" T 560 x 86 mm |

26.00" OD x 3.50" T 660 x 89 mm |

|

| Product Weight | 100 lbs 45 kg |

240 lbs 110 kg |

450 lbs 200 kg |

220 lbs 100 kg |

300 lbs 140 kg |

|

Interested in Getting a Quote?

Technical Details

- Motor drives and controls

- Encoders and digital readouts (DRO)

- Vacuum worktable and controller to hold sensitive lightweight parts safely and securely

- Custom bolt circle patterns

- Standard and custom size clear apertures

- ABTech Precision Centering Fixtures

- Custom fixturing and work holder tooling

- Gage stands

- Electronics packages including MIcroForm and FormCheck

- Granite surface plates

- Structural steel frames with passive vibration isolation leveling feet

- Certified 2µ” round master test ball and cover

Air-Bearing Rotary Tables We Offer

AT Series – Rotary Air Bearing Table

AT300 Rotary Air Bearing

HDRT Series – Rotary Air Bearing Table

HDRT 3000

Custom Large Clear Aperture

Custom Grind Table

Custom 17" Clear Aperture Air Bearing

AT100

AT 200 Direct Drive 1.25arcsec accuracy

AT 100 Foot Mount

AT 200 with variable speed motor, friction clutch and onboard DRO

AT 200 Direct Drive with/ TC8

AT 200 Wet Grind Tableaccuracy

Motor Drive Options

With proper selection and integration of high-performance brushless DC servo motors ABTech’s air bearing rotary tables provide ultra-smooth and precise rotary motion. With high torque, high performance motor drives, our motion experts will gather your specific requirements and work closely with our motor suppliers to create/select a motor drive that suits your specific application. Whether you need sub-micron position accuracy with minimal settle time and stringent following error specifications, high-speed constant motion, or a combination of both there is an ABTech rotary table that will meet your needs.

The motor drives are designed to accommodate a wide range of precision motion applications such as optical metrology; circular geometry gages; and micro machining with ultra-precision scanning, velocity control, speed regulation and precision indexing.

ABTech’s modular design approach facilitates multiple system configurations to optimize the price-for-performance required in your application. This approach allows the user to define the level of control desired for the most cost-effective solution. Our complete engineering services allow us to respond quickly to provide a solution to your O.E.M. requirements for ultra-precision rotary motion.

See What Our Customers are Saying

"We use 2 ABTech air-bearing spindles with tip/tilt and centering capability in our facility. These units are used for precision assembly and final metrology. We have never had an issue with either one, and the ABTech team is a great partner for us. We will be adding more systems as our young organization continues to grow".

Jayson Tierson

President, Vertex Optics

See What Our Customers are Saying

“Thanks a lot for your help [with remote technical support provided for the system installed at the South Pole]. Your rapid, informative correspondence was invaluable. Hopefully I won't be bothering you with any further questions, but it's good to know you're willing.”

Morgan Hedges

Post-Doctoral Research Associate, Princeton University

Benefits and Advantages

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan, risus sem sollicitudin lacus, ut interdum tellus elit sed risus. Maecenas eget condimentum velit, sit amet feugiat lectus. Class aptent taciti sociosqu ad litora torquent per conubia nostra.

Maecenas eget condimentum velit, sit amet feugiat lectus. Class aptent taciti sociosqu ad litora torquent per conubia nostra.

Lorem Ipsum Dolor Sit Amet Consectetur Adipiscing ?

Adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan lorem ipsum dolor sit amet.

Lorem Ipsum Dolor Sit Amet Consectetur Adipiscing ?

Adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan lorem ipsum dolor sit amet.

Lorem Ipsum Dolor Sit Amet Consectetur Adipiscing ?

Adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan lorem ipsum dolor sit amet.

Lorem Ipsum Dolor Sit Amet Consectetur Adipiscing ?

Adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan lorem ipsum dolor sit amet.

FAQ's

Some Lorem ipsum faqs will be here with subheading

Who we are working with?

Adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan lorem ipsum dolor sit amet.

What is the process of purchasing

Adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan lorem ipsum dolor sit amet.

Lorem Ipsum Dolor Sit Amet Consectetur Adipiscing ?

Adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan lorem ipsum dolor sit amet.

Lorem Ipsum Dolor Sit Amet Consectetur Adipiscing ?

Adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan lorem ipsum dolor sit amet.

Why choose us

Aptent taciti sociosqu litora torquent

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan, risus sem sollicitudin lacus, ut interdum tellus elit sed risus.