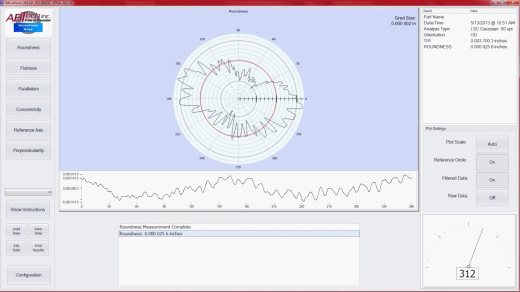

Our Familiar and Straightforward Interface

- Increases productivity,

- Streamlines training, and

- Offers the highest degree of operator flexibility

The hardware platform is critical to ensure accuracy and durability, but it’s the software that separates a functional gage from a truly usable and productive one. For the shop floor, the software that comes with every MicroForm gage offers a familiar and intuitive navigation. And for the quality control lab, it provides full function analysis.

Operators of Every Skill Level Can Use Our Gages

We understand the challenges companies face in finding qualified operators. Many competitive products are so complex that they force companies to assign highly skilled personnel as operators. With the industry’s on-going skills shortage, this can result in gages going underutilized or unused altogether. In response, a primary design goal of our software was for it to be quickly assimilated by operators at all levels, allowing flexibility and productivity right out of the box.

Full Functionality Made Easy

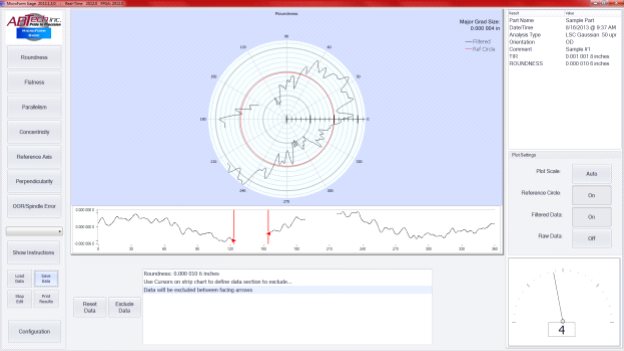

All the most common form measurements are included; covering roundness, flatness, concentricity (in and out of plane), parallelism and perpendicularity. Our unique RunOut feature displays both digital and analog versions of your part’s runout. It captures the max and min values along with their respective angular locations, and calculates the total runout. This versatile feature is ideal for quick in-process checks or to align parts for more detailed form measurements.

Need to measure parts with keyways or bored holes? MicroForm allows user to define parameters that will automatically remove interruptions in a surface from measurements. You also have the option to manually edit out individual segments by using our easy drag and drop feature on the results plot.

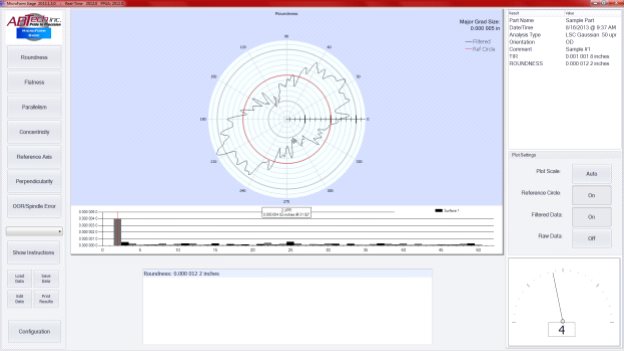

Want to analyze the frequency of undulations in your part to identify machining or grinding issues? Just activate MicroForm’s Harmonic Analysis feature to display a bar graph of all frequencies and their amplitudes on the same page as your form measurement results.

Dual Probes Speed Throughput

To further speed the measurement process, all MicroForm gages offer a dual probe option. The ability to check part alignment and/or runout of two surfaces at the same time dramatically improves throughput. And you have a choice of display views: individual probe or sum/differential display. Concentricity, parallelism and perpendicularity measurements requiring reference datums can also be performed simultaneously.

Interface Maximized for Both the Novice and Experienced User

To simplify and accelerate the training process, on screen “step-by-step” instructions are available to assist the novice operator through each measurement in a way that doesn’t reduce the efficiency of experienced users.

To meet your particular needs, the software has built in customizable displays and output options. User selectable scale resolutions and SAE or metric units offer full flexibility for all of your part requirements. Add a part number and comments to capture all the details pertinent to the measurement, then display or print the results. You can even add your company logo or contact information to the results document for a professional final touch.

For statistical process control (SPC) and traceability, results and graphical charts can quickly be saved, printed, converted to PDF, or exported using the available Ethernet network connection.

Interested in Getting a Quote?

See What Our Customers are Saying

"We use 2 ABTech air-bearing spindles with tip/tilt and centering capability in our facility. These units are used for precision assembly and final metrology. We have never had an issue with either one, and the ABTech team is a great partner for us. We will be adding more systems as our young organization continues to grow".

Jayson Tierson

President, Vertex Optics

See What Our Customers are Saying

“Thanks a lot for your help [with remote technical support provided for the system installed at the South Pole]. Your rapid, informative correspondence was invaluable. Hopefully I won't be bothering you with any further questions, but it's good to know you're willing.”

Morgan Hedges

Post-Doctoral Research Associate, Princeton University

Benefits and Advantages

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan, risus sem sollicitudin lacus, ut interdum tellus elit sed risus. Maecenas eget condimentum velit, sit amet feugiat lectus. Class aptent taciti sociosqu ad litora torquent per conubia nostra.

Maecenas eget condimentum velit, sit amet feugiat lectus. Class aptent taciti sociosqu ad litora torquent per conubia nostra.

Lorem Ipsum Dolor Sit Amet Consectetur Adipiscing ?

Adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan lorem ipsum dolor sit amet.

Lorem Ipsum Dolor Sit Amet Consectetur Adipiscing ?

Adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan lorem ipsum dolor sit amet.

Lorem Ipsum Dolor Sit Amet Consectetur Adipiscing ?

Adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan lorem ipsum dolor sit amet.

Lorem Ipsum Dolor Sit Amet Consectetur Adipiscing ?

Adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan lorem ipsum dolor sit amet.

FAQ's

Some Lorem ipsum faqs will be here with subheading

Who we are working with?

Adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan lorem ipsum dolor sit amet.

What is the process of purchasing

Adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan lorem ipsum dolor sit amet.

Lorem Ipsum Dolor Sit Amet Consectetur Adipiscing ?

Adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan lorem ipsum dolor sit amet.

Lorem Ipsum Dolor Sit Amet Consectetur Adipiscing ?

Adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan lorem ipsum dolor sit amet.

Why choose us

Aptent taciti sociosqu litora torquent

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Etiam eu turpis molestie, dictum est a, mattis tellus. Sed dignissim, metus nec fringilla accumsan, risus sem sollicitudin lacus, ut interdum tellus elit sed risus.